Albemarle is a trusted partner with automotive manufacturers and the battery value chain to deliver critical elements for lithium-ion batteries.

As the world continues to electrify, Albemarle is pioneering technologies that will drive greater energy density for increased range and reduced weight and volume as well as closed-loop solutions for the lithium supply chain.

POWER IN NUMBERS

- +3.2 MMt

- Projected global lithium demand by 2030

- 59%

- Projected EVs share of global auto market by 2030

- 86%

- Amount of battery material supply from end-of-life BEVs by 2035

ADVANCEMENTS

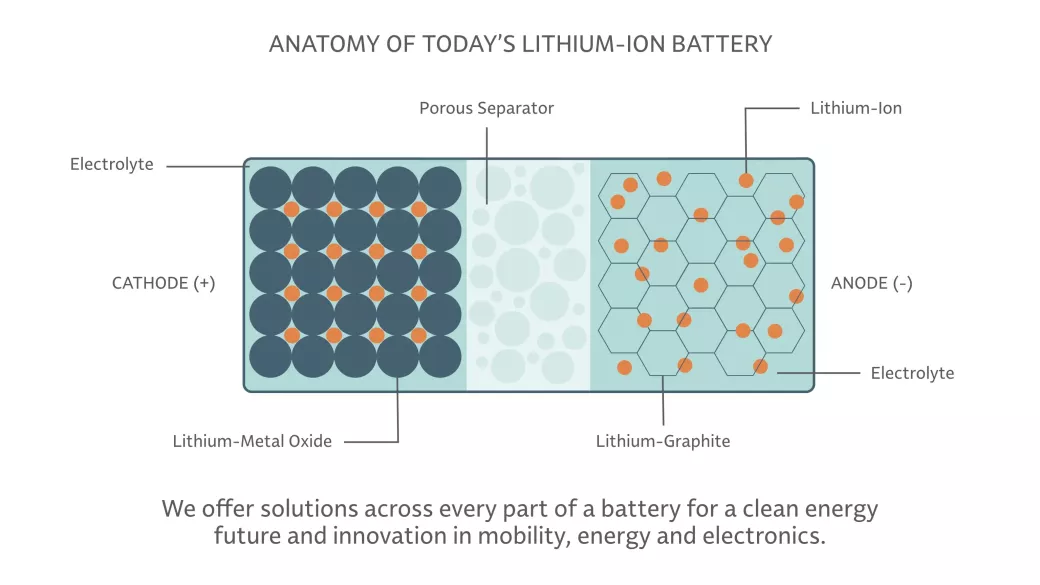

Unlocking Value in All Parts of the Battery Cell

Lithium-ion batteries have conventionally consisted of a cathode, a graphite anode and a liquid electrolyte.

- Lithium metal anodes are critical in delivering significant improvements in energy density

- Transferring from flammable liquid electrolyte to semi-solid and solid-state architecture can improve safety and performance

- Rapid innovation in lithium materials indicates yet more improvements

ADVANCEMENTS

EV Range Improvements from Battery Materials

Through advancements in battery cell materials, significant increases in the range of EVs are being realized – with a 40% increase in average range projected by 2030. That’s the equivalent of a 185-mile range EV getting a range boost to 260 miles.